Standardized Design: Manufactured in strict compliance with relevant standards of the American Society of Mechanical Engineers (ASME), ensuring the uniformity and interchangeability of key parameters such as flange dimensions, pressure ratings, and sealing face types. This facilitates procurement and installation in engineering projects.

I. Core Product Features

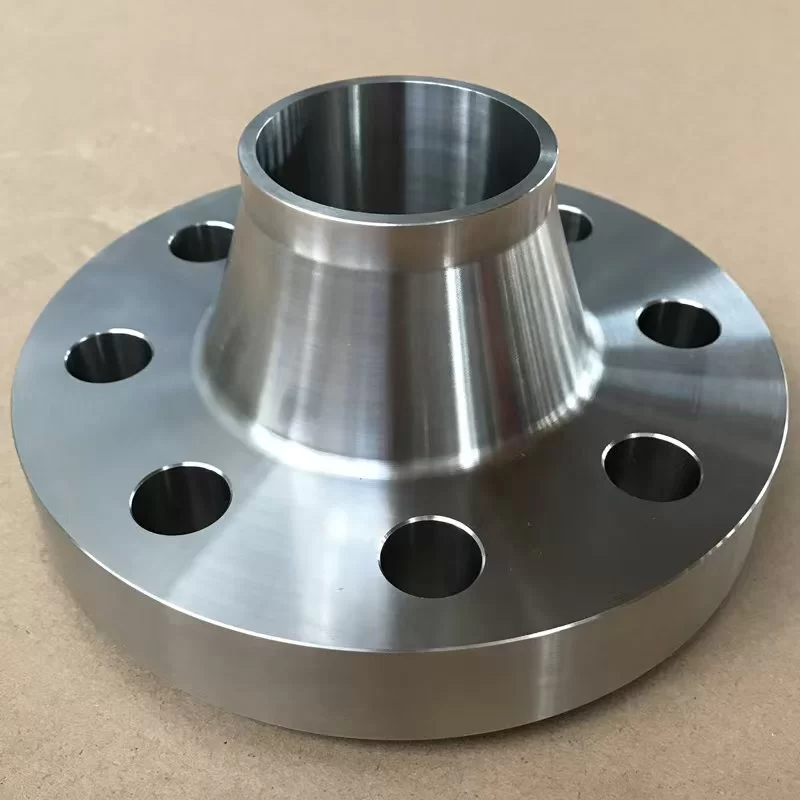

1.Standardized Design: Manufactured in strict compliance with relevant standards of the American Society of Mechanical Engineers (ASME), ensuring the uniformity and interchangeability of key parameters such as flange dimensions, pressure ratings, and sealing face types. This facilitates procurement and installation in engineering projects.

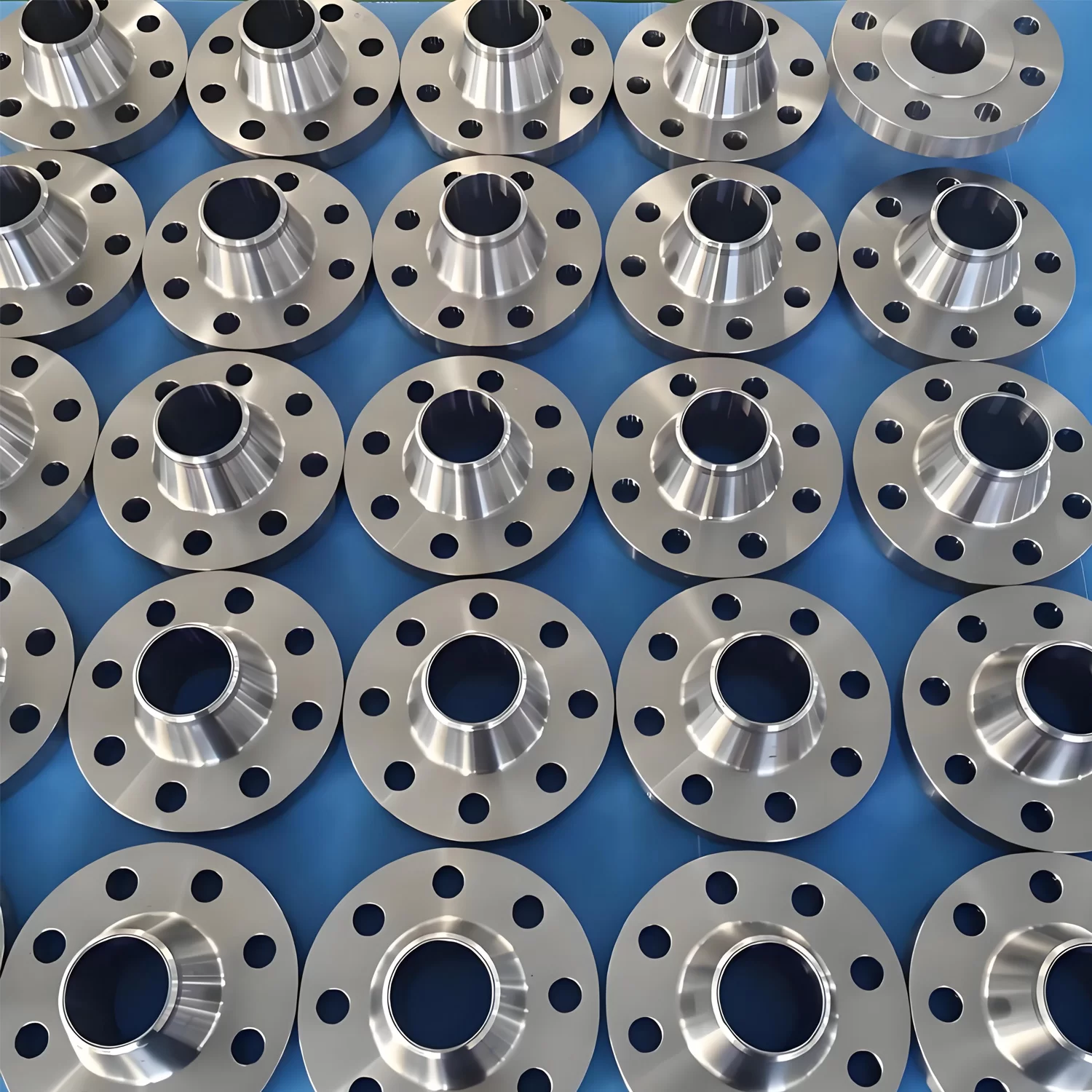

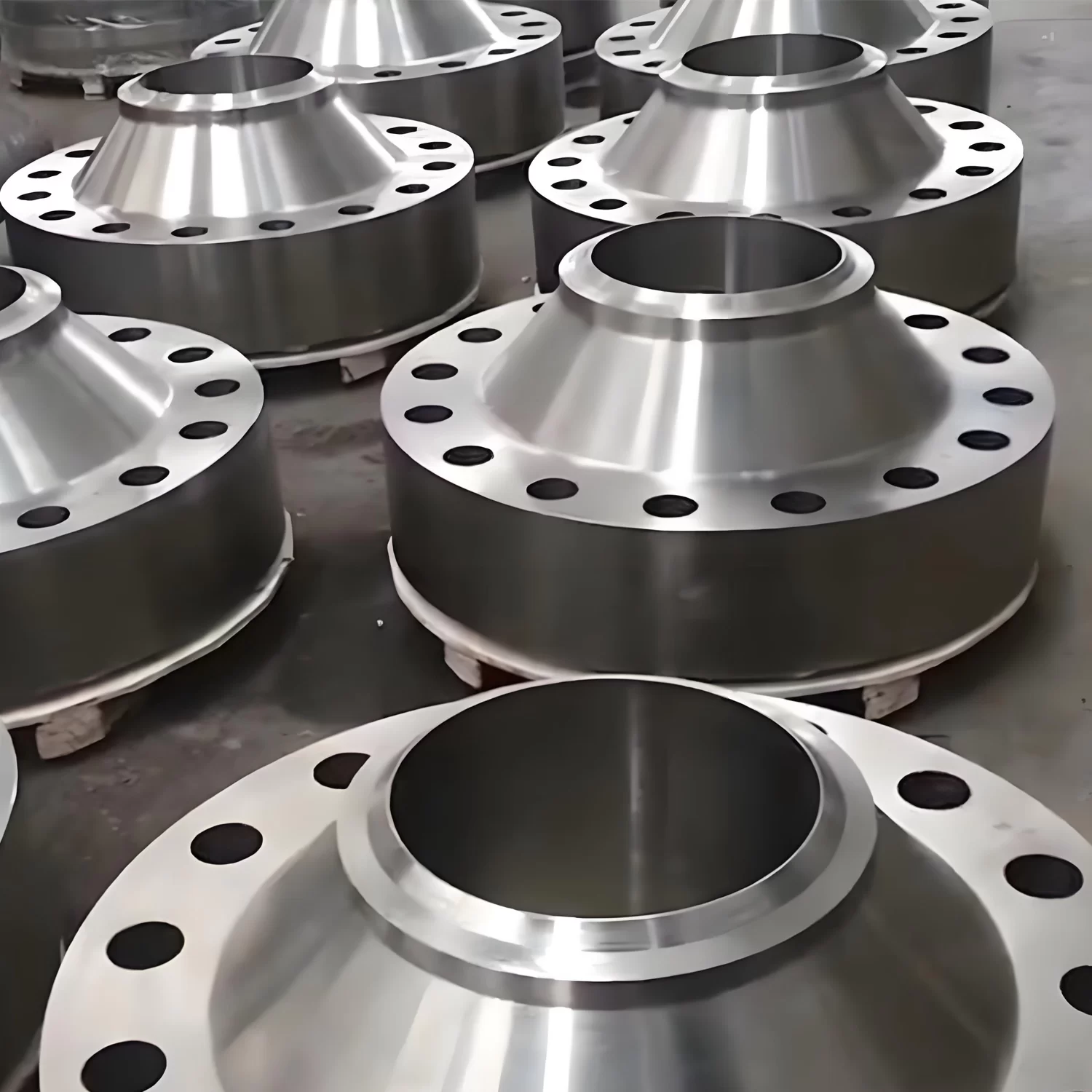

2. Butt Weld Connection Structure: The flange neck is butt-welded to the pipeline. This connection method integrates the flange and pipeline into a single unit, delivering exceptional structural strength and rigidity. It can effectively resist loads such as vibration, thermal expansion, and pressure fluctuations in the pipeline system, making it suitable for high-pressure, high-temperature, and critical service pipeline applications.

3. Wide Pressure Rating Coverage: In accordance with ASME standards, the pressure ratings of American Standard weld neck flanges include Class 150, 300, 400, 600, 900, 1500, 2500, etc. Different pressure ratings correspond to varying flange thicknesses, bolt specifications, and quantities, meeting the requirements of various operating conditions from low pressure to ultra-high pressure.

4. Diversified Sealing Faces: Common sealing face types include Raised Face (RF), Male-Female Face (MFM), Tongue-Groove Face (TG), Ring Joint (RJ), etc.

●RF flanges offer strong versatility;

●MFM and TG faces provide superior sealing performance through tight surface-to-surface contact;

●RJ faces achieve sealing via plastic deformation of metal ring gaskets, suitable for high-temperature, high-pressure (e.g., Class 900 and above) and harsh media environments.

II. Material Selection

1. Carbon Steel: e.g., A105 (forged steel, suitable for medium-low temperature and high pressure), A350 LF2/LF6 (low-temperature carbon steel, suitable for low-temperature environments). Cost-effective and ideal for non-corrosive or weakly corrosive media.

2. Stainless Steel: e.g., 304/304L, 316/316L, 321, 310S. Features excellent corrosion resistance and oxidation resistance, applicable to corrosive media (e.g., acids, alkalis, salt solutions) and high-temperature environments.

3. Alloy Steel: e.g., A182 F11/F22 (chromium-molybdenum steel, suitable for high-temperature and high-pressure steam systems), F5/F9 (high chromium-molybdenum steel, resistant to higher temperatures and corrosion). Designed for high-temperature, high-pressure, and strongly corrosive operating conditions.

4. Other Special Materials: e.g., duplex stainless steel, nickel-based alloys (Hastelloy, Monel, etc.), used in extremely harsh corrosive environments.

III. Application Scope & Advantages

1. Application Scenarios: Due to its high strength, reliable sealing, and standardized design, the weld neck flange is widely used in pipeline systems across industries such as oil and gas exploration and transportation, oil refining and chemical engineering, power generation (thermal power, nuclear power), shipbuilding, water treatment, pharmaceuticals, and food processing. It is particularly suitable for pipeline connections involving high-temperature, high-pressure, flammable, explosive, toxic, or hazardous media.

2. Product Advantages:

●High Connection Strength: Butt-welded connection forms a rigid integral structure between the flange and pipeline, exhibiting excellent tensile, compressive, and bending resistance. It can withstand significant pipeline thrust and torque.

●Reliable Sealing Performance: Long-term stable sealing is achievable through rational selection of sealing face types and gasket materials, effectively preventing media leakage and ensuring safe system operation.

●High Standardization: Globally compatible, facilitating design selection, procurement, installation, and maintenance while reducing project costs and cycles.

●Durability: Manufactured from high-quality materials, and after appropriate heat treatment, it possesses excellent mechanical properties and corrosion resistance, ensuring a long service life.

IV. Executive Standards & Quality Control

1.Executive Standards: Primarily complies with ASME B16.5 (Pipe Flanges and Flanged Fittings), ASME B16.47 (Large Diameter Steel Flanges), and relevant material standards (e.g., ASTM, ASME SA series).

2. Quality Control: Strict quality control is implemented throughout the production process, including:

●Chemical composition analysis of raw materials;

●Mechanical property testing (tensile test, impact test, hardness test);

●Non-destructive testing (ultrasonic testing (UT), magnetic particle testing (MT) to inspect the internal quality of weld joints and forgings);

●Dimensional accuracy inspection (outer diameter, thickness, bolt hole position, etc.);

●Sealing face machining quality inspection.

These measures ensure products meet both standard requirements and customer needs.

Dec 02,25

Characteristics And Common Applications Of Carbon Steel Bending Pipe

The use of bent piping is an essential practice in industrial construction, allowing fluid transfer lines to navigate complex routes, compensate for thermal expansion, and eliminate the need for numerous welded elbow fittings.

Dec 02,25

The Core Role Of The Tee In Pipeline Systems

In the complex architecture of modern pipeline systems—spanning petrochemical plants, municipal waterworks, HVAC networks, and power generation facilities—the tee fitting is arguably one of the most critical and universally employed components.

Dec 02,25

Corrosion-Resistant Flanges For Chemical And Marine Industries

Flanges are indispensable components in piping systems, serving as the critical junctions that allow for connections, maintenance, and isolation of flow.

SUBSCRIBE NEWSLETTER

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.