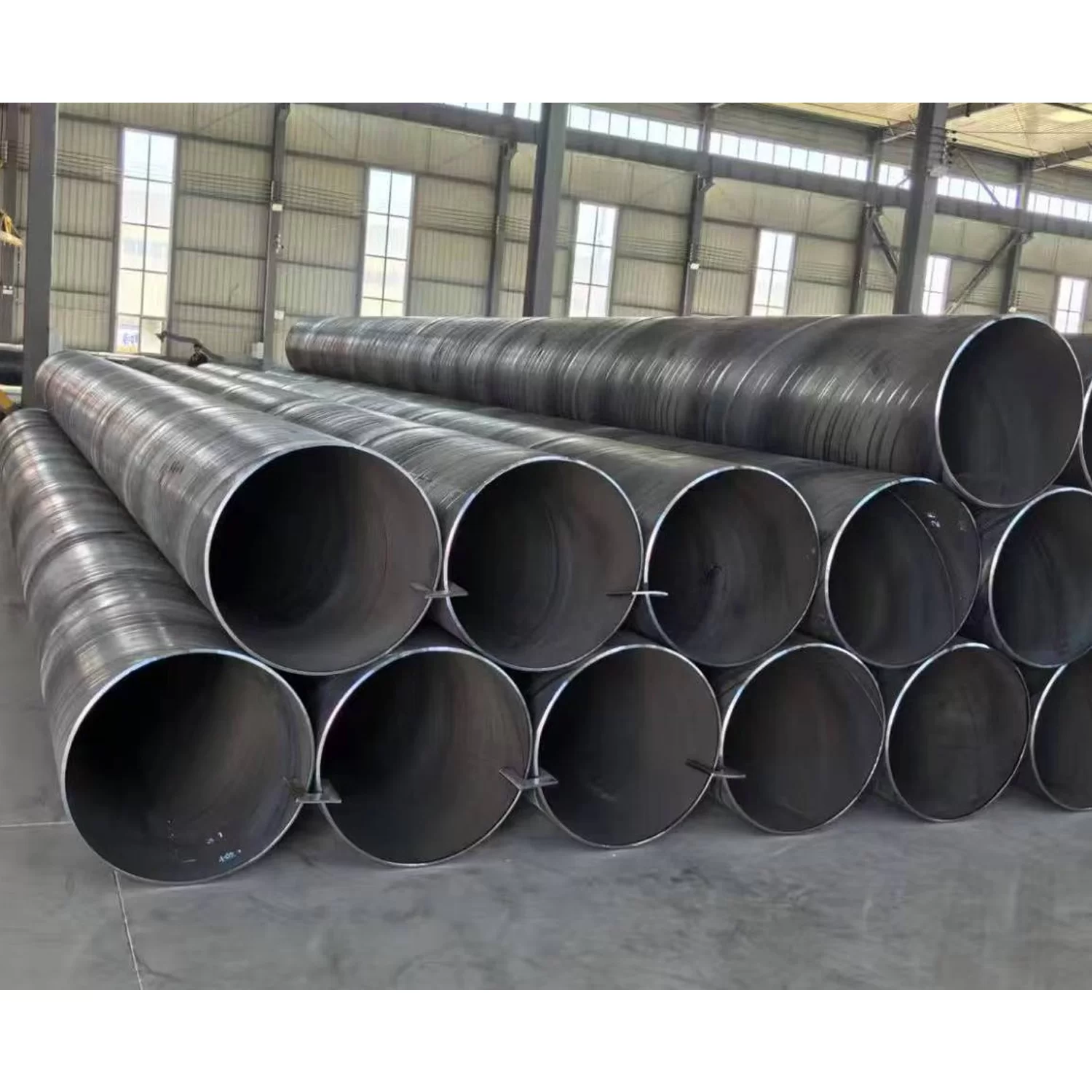

Spiral welded steel pipe is a type of helically seam-welded steel pipe, widely used in numerous industrial fields such as petroleum, natural gas, chemical engineering, water treatment, and building structures. Its production process involves rolling low-carbon structural steel or low-alloy structural steel strips into pipe blanks at a specific helical angle, followed by double-sided submerged arc welding or high-frequency welding. It boasts the following distinctive features and advantages:

I. Executive Standards & Materials

1. Main Executive Standards

●ASTM A252 (Welded and Seamless Steel Pipe Piles)

●ASTM A53 (Seamless and Welded Black and Hot-Dipped Galvanized Steel Pipe)

●API 5L (Specification for Line Pipe)

Different standards correspond to varying application scenarios and performance requirements.

2. Common Materials

Primarily low-carbon steel or low-alloy steel, such as A252 Gr.1/Gr.2/Gr.3, A53 B, API 5L B/X42/X52/X60/X70, etc. These materials offer excellent weldability, toughness, and strength, meeting the transportation or structural needs of different pressure ratings and environmental conditions.

II. Product Specification Range

Spiral welded steel pipes feature a wide specification range and can be customized according to customer requirements:

●Outer Diameter: Typically from 219.1mm (8 inches) to 3620mm (142.5 inches) or larger;

●Wall Thickness: Generally 3.0mm to 25.4mm, with thicker options available for special specifications;

●Length: Standard length 6-12 meters, with fixed-length or random-length products provided based on transportation and installation needs;

●End Treatment: Various options including plain end, beveled end (e.g., V-bevel), and can be equipped with flanges, threaded fittings, etc., according to connection requirements.

III. Production Process Features

1. Forming Process: Advanced spiral forming units are adopted. Through precise guide plate and roller control, steel strips are continuously rolled into stable pipe blanks. During forming, the pipe diameter and roundness can be accurately controlled by adjusting the forming angle, ensuring product dimensional accuracy.

2. Welding Process:

●Mainstream: Double Submerged Arc Welding (DSAW). Welding is performed under flux protection, resulting in high weld quality, deep penetration, and excellent mechanical properties, effectively avoiding defects such as porosity and slag inclusion;

●Alternative: Electric Resistance Welding (ERW) for thin-walled pipes or those with specific requirements, offering higher production efficiency.

3. Online Inspection: Equipped with non-destructive testing (NDT) equipment for welds during production, including X-Ray inspection, Ultrasonic Testing (UT), Magnetic Particle Testing (MT), etc., to conduct 100% inspection of internal and surface weld quality, ensuring each pipe's weld meets standard requirements. Meanwhile, online monitoring of pipe dimensions, straightness, and wall thickness is performed to guarantee product consistency.

IV. Product Performance Advantages

1. High Strength & Toughness: Made from high-quality steel strips, after welding and heat treatment (e.g., normalization), the pipes exhibit high tensile strength, yield strength, and impact toughness. They can withstand high operating pressure and external loads, suitable for high-pressure fluid transportation and structural support.

2. Excellent Pressure Resistance & Sealing: The helical weld runs at a certain angle to the pipe axis, ensuring uniform stress distribution. Compared with longitudinal welded pipes, spiral welded pipes offer superior fatigue resistance and pressure-bearing capacity under the same pressure conditions, making them particularly suitable for long-distance, high-pressure fluid transmission pipelines.

3. Outstanding Economy:

●Can be produced using wide steel strips, achieving high raw material utilization;

●Production equipment features strong flexibility, enabling quick switching between different specifications;

●Lower production costs compared to alternatives;

●Large-diameter spiral pipes can be produced without large steel billets, meeting the needs of large-diameter pipeline projects and reducing overall project costs.

4. Customizable Corrosion Resistance: According to service environments, pipes can undergo internal and external anti-corrosion treatments, such as epoxy coal tar pitch coating, 3-layer Polyethylene (3PE) anti-corrosion coating, Fusion-Bonded Epoxy (FBE) coating, galvanization, etc., significantly extending service life in corrosive environments such as soil, seawater, and chemical media.

V. Main Application Fields

1. Oil & Gas Transmission: As a core product of API 5L standard, widely used in long-distance oil and gas transmission trunk pipelines, oilfield gathering and transportation pipelines, and urban gas pipelines, meeting the requirements of high-pressure, high-flow rate media transmission.

2. Municipal Engineering: Used in urban water supply and drainage pipelines, sewage treatment pipelines, and heating networks. Large-diameter spiral pipes can effectively reduce the number of pipeline installations, lowering construction difficulty and costs.

3. Building Structures: Applied in steel structure buildings, bridges, piling, and wharf construction as support columns, beams, or pile pipes, enhancing structural safety through high strength and stability.

4. Chemical & Power Industry: Used in chemical raw material transmission pipelines, power plant circulating water pipelines, and desulfurization/denitrification pipelines. Corrosion-resistant treated pipes can adapt to harsh media environments such as acids and alkalis.

5. Water Conservancy & Agriculture: Utilized in farmland irrigation, water conservancy hub projects, and water diversion pipelines. Features of large diameter and high flow rate meet the needs of large-scale water transmission.

VI. Quality Control & Standard Certification

The production of spiral welded steel pipes strictly complies with ASTM, API, and other standards. A comprehensive quality assurance system is established covering raw material procurement (with mill certificates required), production process control (process parameter recording, online inspection), and finished product testing (mechanical property testing, chemical composition analysis, hydrostatic testing, etc.). Products can obtain ISO 9001 quality management system certification, API 5L product certification, etc., ensuring each batch meets international standards and customer requirements.

VII. Packaging & Transportation

To ensure product integrity during transportation and storage:

●Pipes are typically bundled with steel strips, with protective caps installed at both ends to prevent end deformation or corrosion;

●For anti-corrosion treated pipes, anti-scratch measures (e.g., wrapping protective film or using special brackets) are adopted;

●Transportation methods (road, railway, or sea freight) are selected based on quantity and distance to ensure safe delivery to customer sites.

VIII. Comparative Advantages Over Other Steel Pipes

Comparison Item | Spiral Welded Steel Pipe | Longitudinal Welded Steel Pipe | Seamless Steel Pipe |

Large-Diameter Production | More advantageous for large-diameter, thick-walled products | Limited by strip width for large diameters | High production difficulty and cost for large diameters |

Weld Performance | Uniform weld distribution, superior pressure resistance and deformation resistance | Concentrated weld stress, lower fatigue resistance under high pressure | No weld, but higher cost |

Production Efficiency | High, suitable for mass production | Medium | Low |

Cost-Effectiveness | High, especially for large-diameter, medium-low pressure projects | Medium | Low |

Dec 02,25

The Core Role Of The Tee In Pipeline Systems

In the complex architecture of modern pipeline systems—spanning petrochemical plants, municipal waterworks, HVAC networks, and power generation facilities—the tee fitting is arguably one of the most critical and universally employed components.

Dec 02,25

Corrosion-Resistant Flanges For Chemical And Marine Industries

Flanges are indispensable components in piping systems, serving as the critical junctions that allow for connections, maintenance, and isolation of flow.

Dec 02,25

Characteristics And Common Applications Of Carbon Steel Bending Pipe

The use of bent piping is an essential practice in industrial construction, allowing fluid transfer lines to navigate complex routes, compensate for thermal expansion, and eliminate the need for numerous welded elbow fittings.

SUBSCRIBE NEWSLETTER

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.