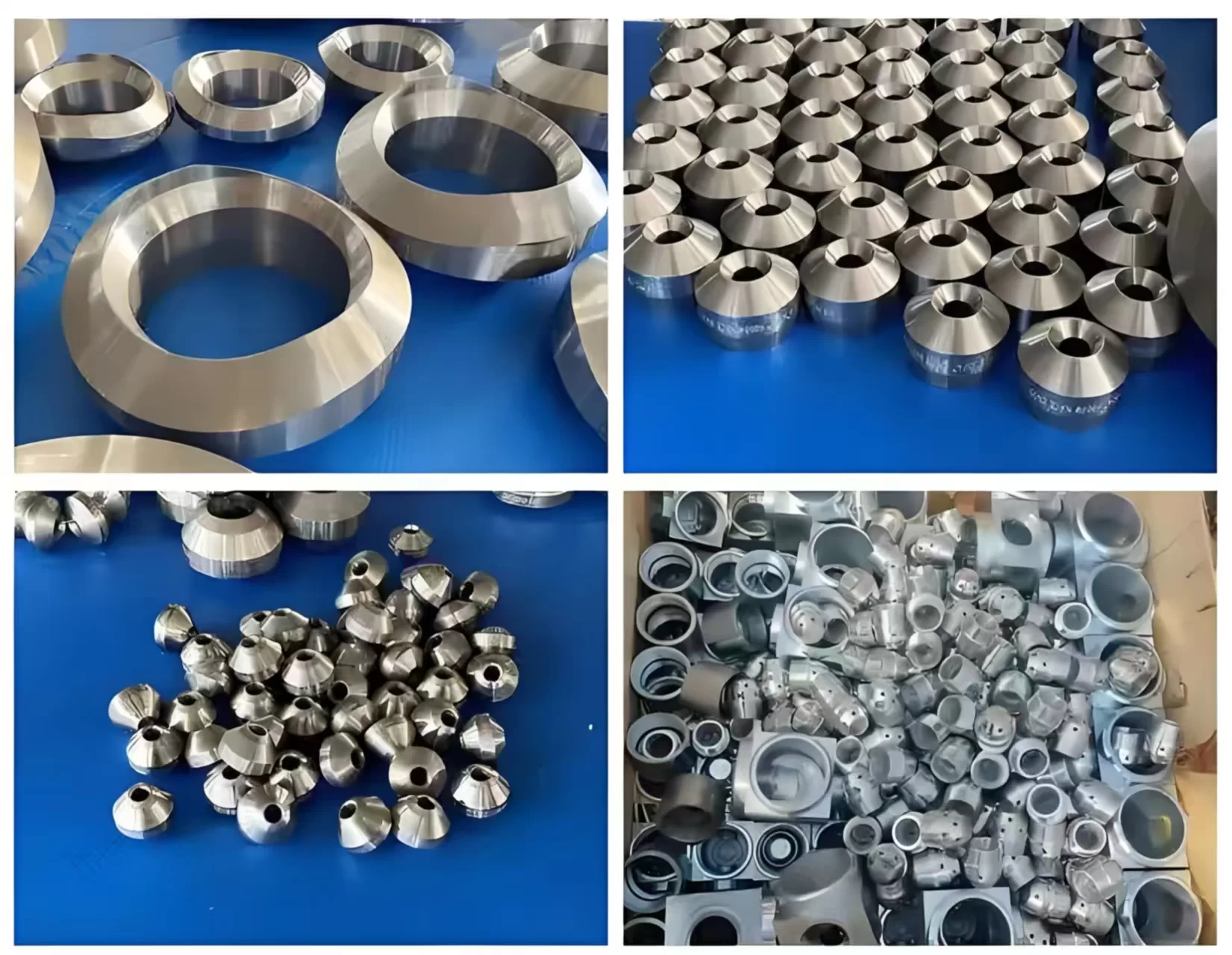

They mainly include elbows, tees, crosses, reducers, caps, pipe sockets and other types. The connection method is simple, fixed through plug-in assembly, saving installation time with strong sealing performance. They are usually equipped with sealing rings, fillers and other structures to prevent medium leakage. Their core function is to realize steering, branching, diameter changing or sealed butt joint of pipeline systems.

The connection forms of socket fitting series include: socket weld connection (SW), butt weld connection (BW), threaded connection (TR), and flexible elastic double fusion socket connection, forming stable joints to ensure the sealing performance and pressure-bearing capacity of the pipeline system.

Pressure rating of socket fittings: Generally, the pressure ratings of fittings with socket weld and butt weld connections are 3000LB, 6000LB, and 9000LB. The pressure ratings of fittings with threaded connections are 2000LB, 3000LB, and 6000LB.

Common materials: Including carbon steel, stainless steel, alloy steel, etc., suitable for high-pressure and high-temperature environments. Non-metallic polypropylene (PPR) is suitable for corrosion-resistant or light-load scenarios, such as water supply and drainage systems.

Reference manufacturing standards for fittings: ASME B16.11, MSS SP-83, MSS SP-79, MSS SP-97, MSS SP-95, GB/T 14383-2008, SH/T3410-96, GD2000, etc. Non-standard customization can also be carried out according to drawings.

Application fields: Socket fittings are mainly applicable to petrochemical, pharmaceutical and healthcare, electric power, aerospace, military industry, fire protection, metallurgy, shipbuilding, gas, nuclear power, environmental protection and other departments and fields requiring high pressure-bearing capacity and precise dimensions.